Top And Bottom Web Films

For packaging, the product size, shape and function will typically determine the ideal packaging method to choose. The medical device industry frequently utilizes flexible packaging that incorporates top sealing and bottom forming webs for unique structures. When the product requires a more rigid bottom tray, then flexible lidding film and foils are used for desired seal strength and barrier properties. In the food and industrial markets there are many variables and factors in choosing the right structure for the product. Variables such as the machine type (such as horizontal and vertical form, fill, seal), the barrier properties needed to maintain freshness, the seal strength to ensure packaging integrity, and ease of opening for the consumer are just some of the factors that need to be taken into consideration. It can seem overwhelming when figuring all this out for a new product and when changes are being made for an existing product line. Our technical team can help you find the solution you need to create the right combination of materials and functionality.

Product Highlights

Product Description

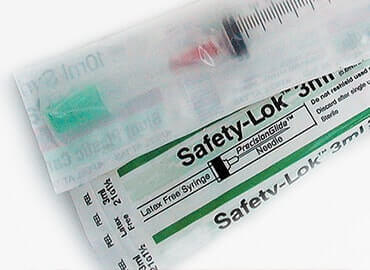

Top and Bottom Webs used within the medical device packaging industry

Capabilities Applied/Processes

Printing and finishing on flexographic presses

Material Used

Heat sealable polyethylene

Colors

Up to 8 colors

In process testing performed

- Ink adhesion

- Print copy to standard

- Registration

Industry for Use

- Pharmaceutical

- Healthcare

- Medical Device